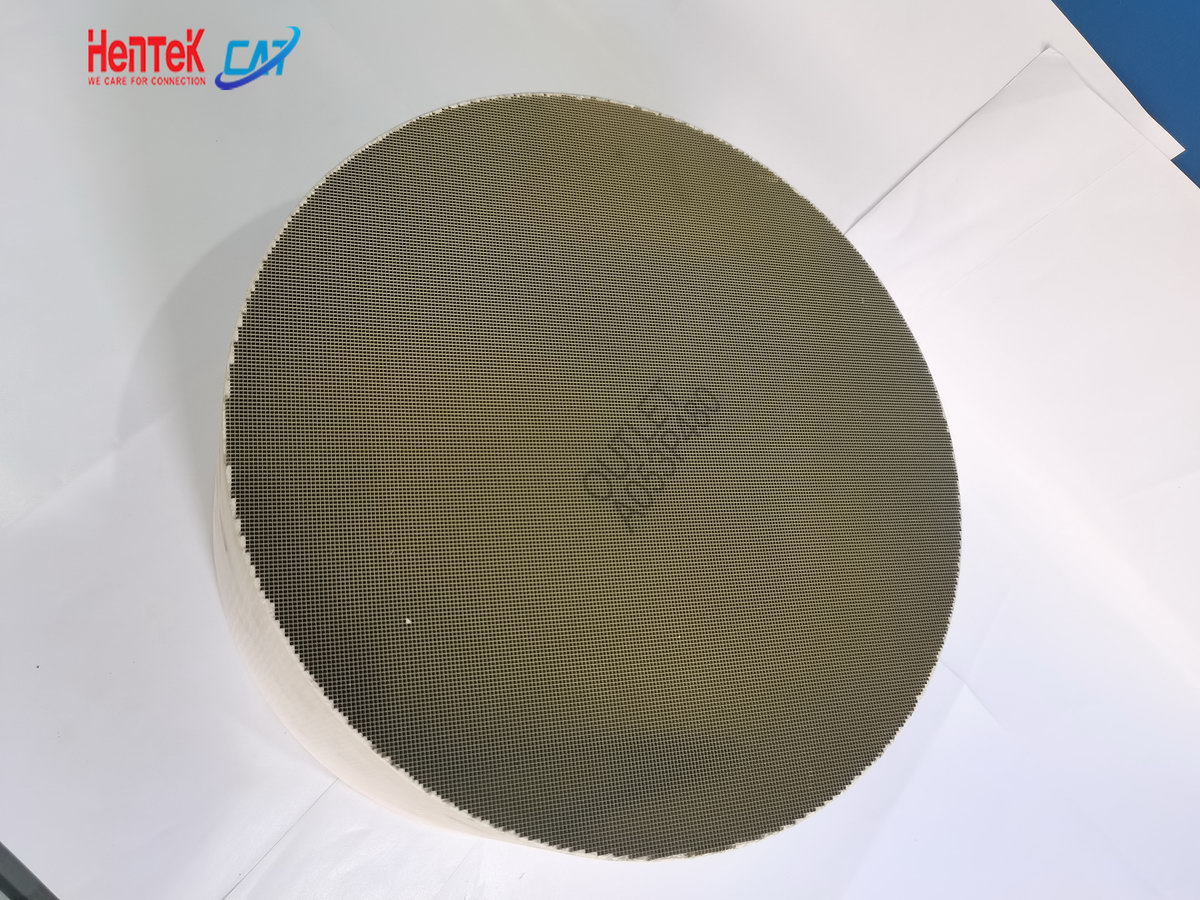

Selective Catalytic Reduction Catalyst

Selective Catalytic Reduction Catalyst

SCR is a treatment process for nitrogen oxides in the exhaust emissions of diesel vehicles, that is, under the action of catalysts, the nitrogen oxides in the exhaust gas are reduced to nitrogen and water that are harmless to air pollution.

Suitable for after-treatment of diesel engine NOx emissions. At the front end of the SCR catalyst, urea is introduced as a reducing agent. After the urea is hydrolyzed to NH3, the NO and NO2 in the exhaust gas are reduced to N2, and NOx is effectively removed under the oxygen-enriched condition of the diesel engine. It has good low temperature activity, wide temperature window and stability, and can meet the Euro V emission standard when matched with the whole machine. The products are suitable for light-duty diesel vehicles (such as cars, SUVs, MPVs) on roads, heavy-duty diesel vehicles (such as buses, heavy trucks, forklifts, etc.), as well as other non-road use diesel engine fixed equipment or devices.

SCR Technical Features:

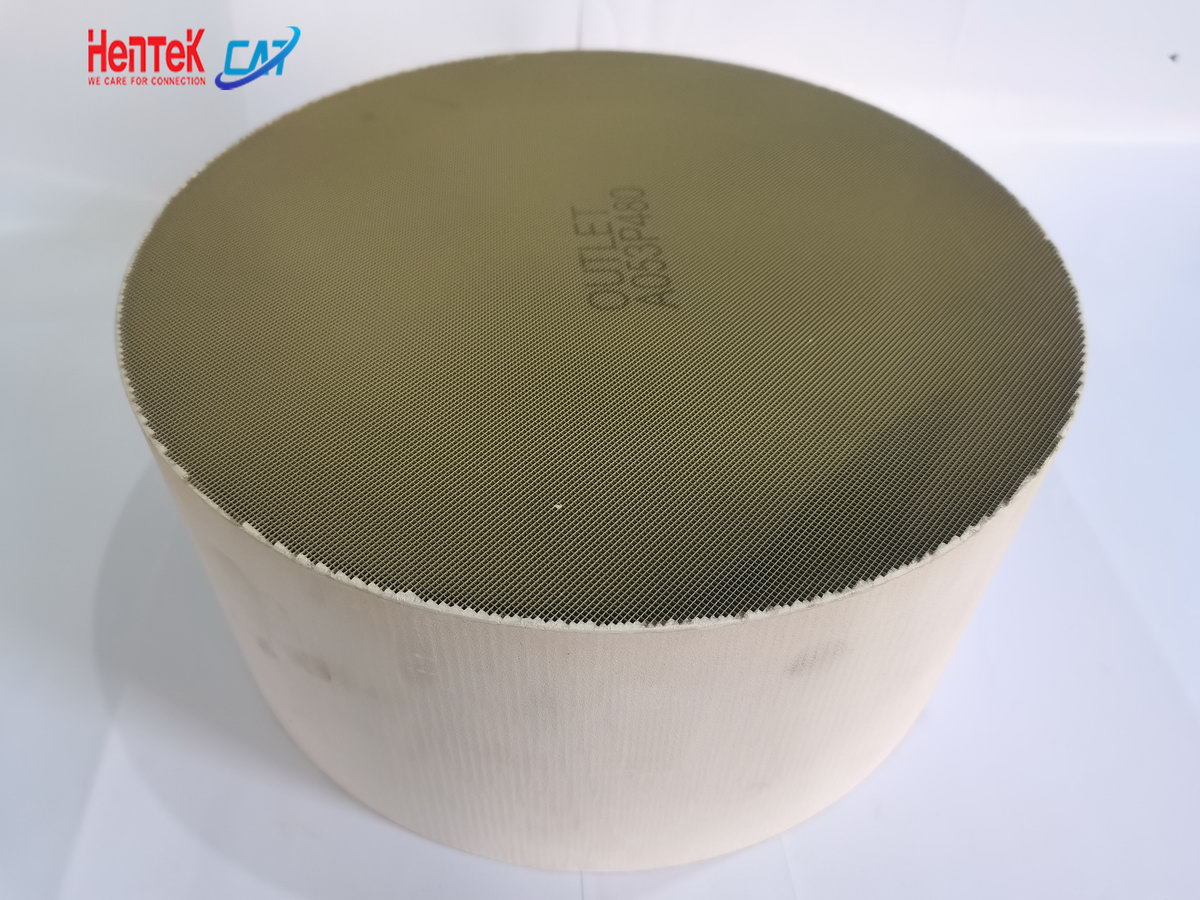

Selective catalytic reduction (SCR) catalyst is a high-tech product widely used in thermal power plants, coal-fired power plants, waste incineration plants, iron and steel plants, fertilizer plants, nitric acid plants, cement plants, petrochemical chemical plants and other industries which need to reduce the NOx emissions. Selective catalytic reduction (SCR) catalyst is a denitration catalyst in the appropriate temperature, using ammonia (NH3) as the reducing agent, take the advantage of the reducing agent selective, preferentially reaction with industrial flue gas of nitrogen oxide (NOx), NOx is converted into no pollution of nitrogen and water, and NOx reduction efficiency is as high as above 90%. our SCR de-nitrogen catalyst was made by using cordierite honeycomb ceramics as the support, using TiO2、CuO、V2O5、Rare earth and WO3 as the main active components. It has great advantages in strength and prevention of fly ash clogging , wearing and anti-poisoning.

| Serial No. | Test Items | Technical Specification |

| 1 | Carrier specifications | 150×150×50, Wall thickness= 3.7±0.1 |

| 2 | NOx concentration | ≤5000ppm |

| 3 | Reductive agent | Liquid ammonia, ammonia water or urea |

| 4 | Space velocity | 3000~10000 h-1 |

| 5 | operation temperature Optimal operation temperature | 150°C-420°C 260°C-300°C |

| 6 | NOx concentration | ≥90﹪ |

| 7 | Service life | ≥2years |

| 8 | Ammonia escape ratio | ≤30ppm |

| 9 | Bulk density | 0.72±0.05g/ml |

| 10 | Crushing strength | ≥14 MPa(Front) ≥4 MPa(Side) |

| 11 | Coating loading | >8.0% |

| 12 | Active Metal oxide loading | >9.0% |

| 13 | Expulsion rate | <1% |

| 14 | Appearance | Pure black |

| 15 | Package | Moisture-proof and Sealed |

Competitive Advantage:

1. Good dispersion of precious metals;

2. Lower ignition temperature;

3. Good high temperature resistance;

4. Good anti-toxicity

5. Life indicators: 50,000 kilometers for in-use vehicles and 200,000 kilometers for new production vehicles.

SCR

SCR

Technical Parameter

Most specifications can be made, and less commonly used specifications can be customized. The following specifications are for reference.

| Type | Shape | Number of holes | Wall thickness(mm) | Outer diameter or long and short diameter range(mm) | Height range(mm) | Tolerance range(mm) |

| SCR Carrier – Below China VI | cylindrical | 300/5 | 0.130±0.025 | 143.8-330.2 | 76.2-178 | ±1.5 |

| 300/6 | 0.165±0.025 | |||||

| 300/7 | 0.178±0.025 | |||||

| 300/8 | 0.200±0.025 | |||||

| SCR Carrier – Country VI | cylindrical | 400/4 | 0.114±0.025 | 150-330.2 | 80-155 | ±1.5 |

600/3 | 0.080±0.025 |

Selective Catalytic Reduction Catalyst Application

Motor vehicle exhaust aftertreatment catalyst and converter

— DOC/DPF/SCR: Catalysts for light and heavy diesel vehicles(Euro llI,Euro lV,Euro V,and Euro VI)