Our expert support team is here to help

Wholesale for Aftermarket Aatalytic Converter Replacement

About Us

Who we are

HENTEK CAT is a high-tech enterprise specializing in the R & D, production, sales and related technical services of motor vehicle pollutant emission control catalysts. With leading core technology, strong R & D ability, rich product application experience and lean production and quality management ability, We can provide customers with cost-effective products and services that meet the more stringent emission standards of EURO IV、EURO V、EURO VI.

The enterprise has a team with experts engaged in catalyst technology R & D, production preparation and technical services for many years as the core, employs a number of doctoral tutors and professors as technical support, and carries out industry university research(IUR) cooperation with the college of chemistry of Beijing University of Aeronautics and Astronautics, so as to provide reliable technical support for product development and application with international and domestic advanced level. Catalyst, the core component of automobile three-way catalytic converter, has mastered the technology of fully improving catalyst activity and reducing precious metal content through the technical breakthrough of the company’s R & D department. The company takes professionalism, integrity, sincerity and efficiency as its business philosophy.

After years of research, with leading core technology, strong R & D capability, high-quality after-sales service and management and operation experience of various projects, the company strives to build the most professional and excellent professional team in China. The company attaches great importance to the construction of talent team, formulates detailed training plans for employees, and provides space for talent growth and talent display.

FAQs

You have questions? We

have answers.

Why Choose Us

Learn more about us.

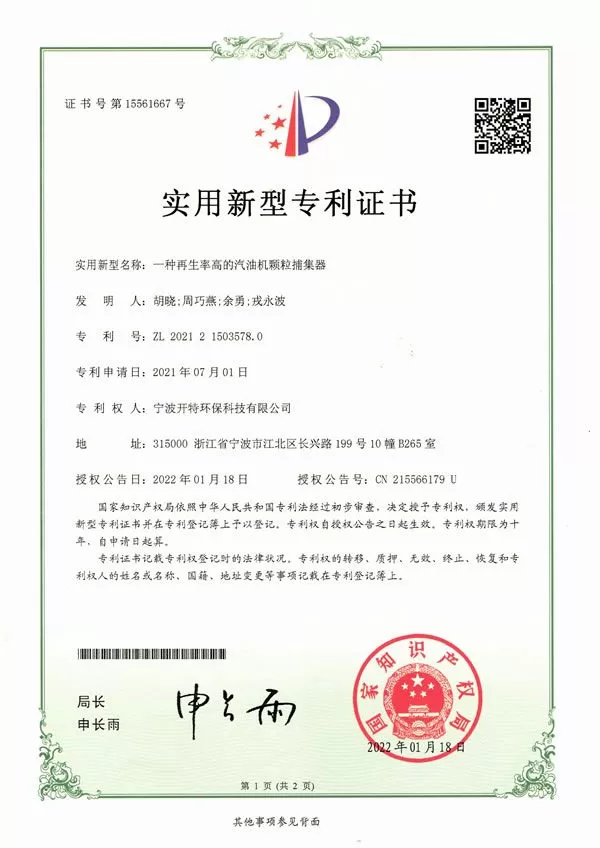

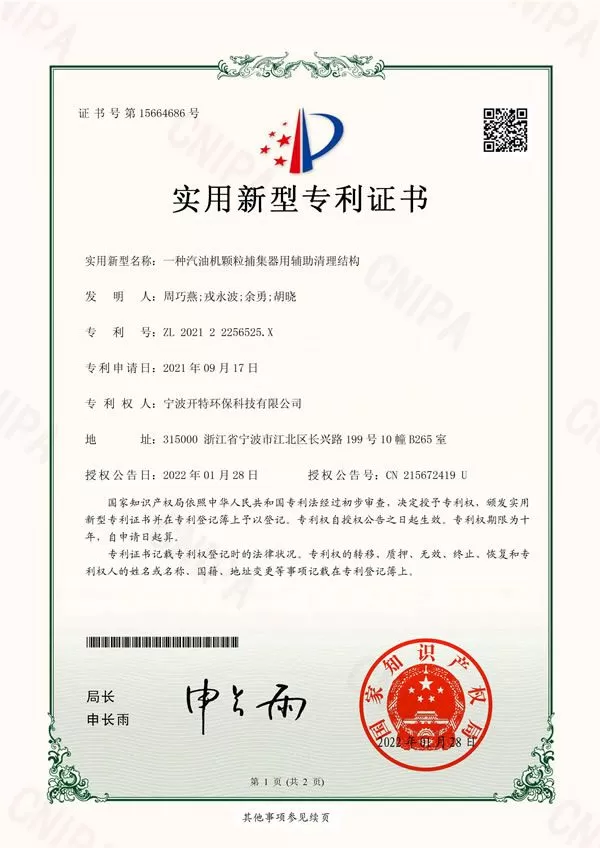

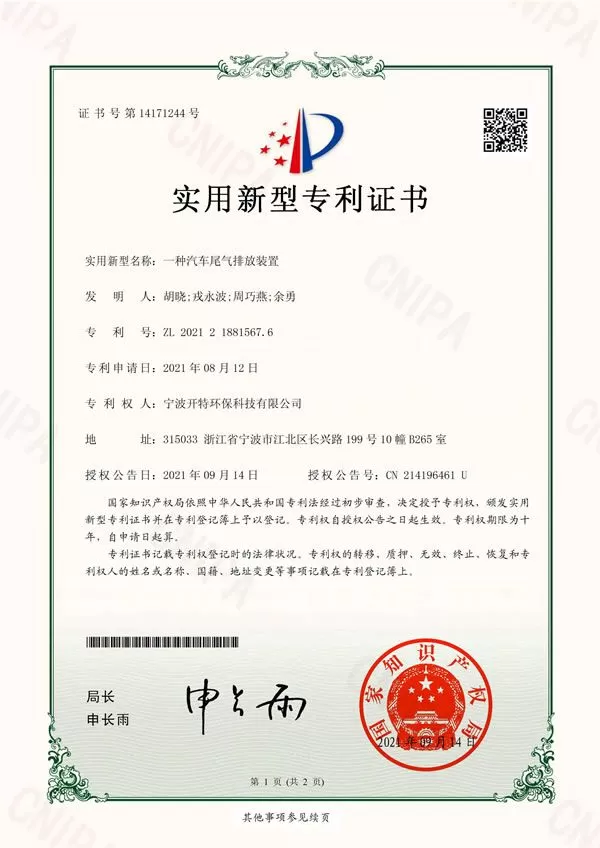

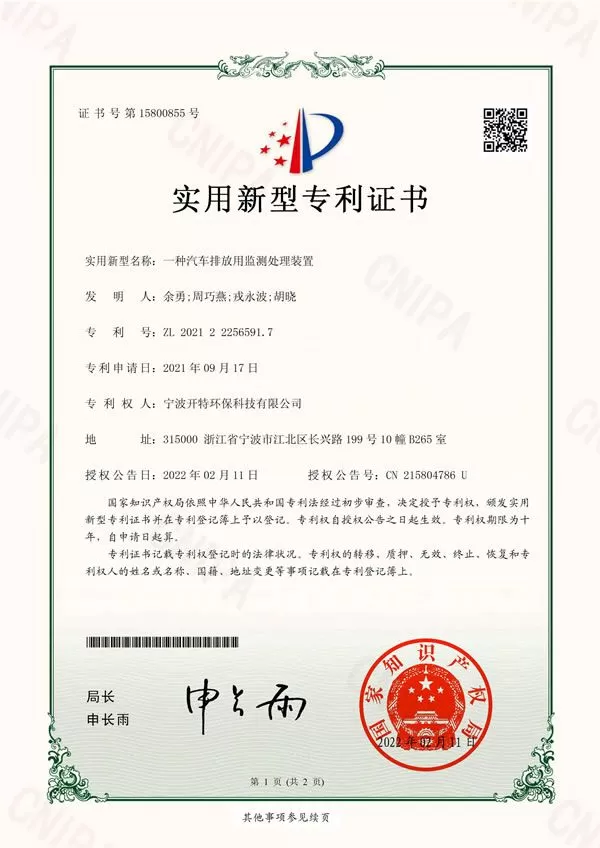

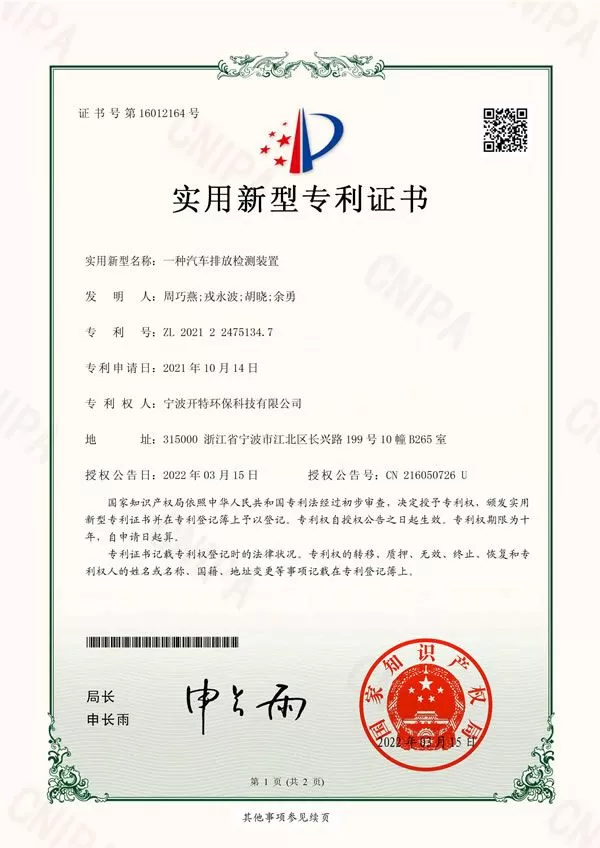

Certificates

Production Technology

More than 20 years of experience. Hired a number of doctoral supervisors, professors for technical support, and a number of domestic colleges and universities cooperation. Cooperated with many domestic test centers.

Processing capacity

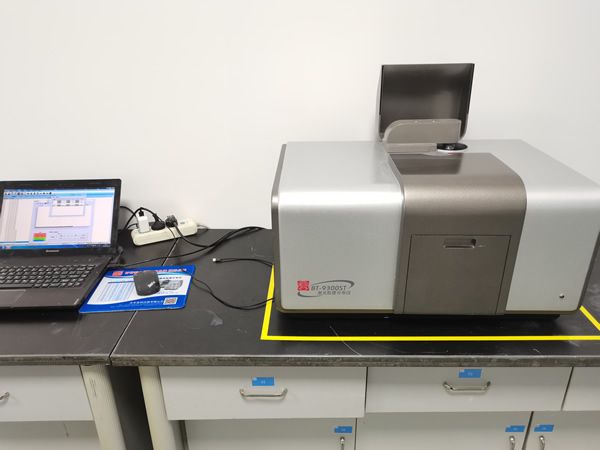

The company has a standard workshop of 3500 square meters. Two batching production lines, two coating lines, four sets of chain furnace, four sets of large ovens, two sample production laboratories, a chemical instrument analysis room, a physical analysis room.

State of the art

More than 20 years of industry experience. Advanced automatic batching system. Advanced production process. Advanced coating technology.

Quality Assurance

Passed ISO9001:2015 quality system certification. There is a complete quality control process of incoming material inspection, process quality, quality inspection and product inspection.

Market recognition

It occupies 30% share of the domestic after-sales market. Occupies more than 55% in high-end vehicles and models with more difficult technology.